COMPANY OUTLINE [URL] http://www.nakaharagp.co.jp

| COMPANY NAME | Nakahara Co., Ltd. |

Design office in intensive factory

Introduction of products

[Core product](Total concurrent engineering) Proposal & designing filled with site sensitivity to extract customer merits. Cooperation in development and verification of prototyping through manufacturing, production control and delivery to JIT. Various types of processing plating, press, laser, painting, etc and designing. Production based on customer needs including proposals, and customer satisfaction. Select Nakahara for 100% Entrust Sheet Metal Processing ! Construction machine cover module set ※ISO・TOC,environment,customers,social contribution

|

|||||||

|---|---|---|---|---|---|---|---|---|---|

| ADVISOR | Executive officer CEO Ichiro (Kikutaro) Nakahara | ||||||||

| REPRESENTATIVE | Executive officer President Tomohei Nakahara | ||||||||

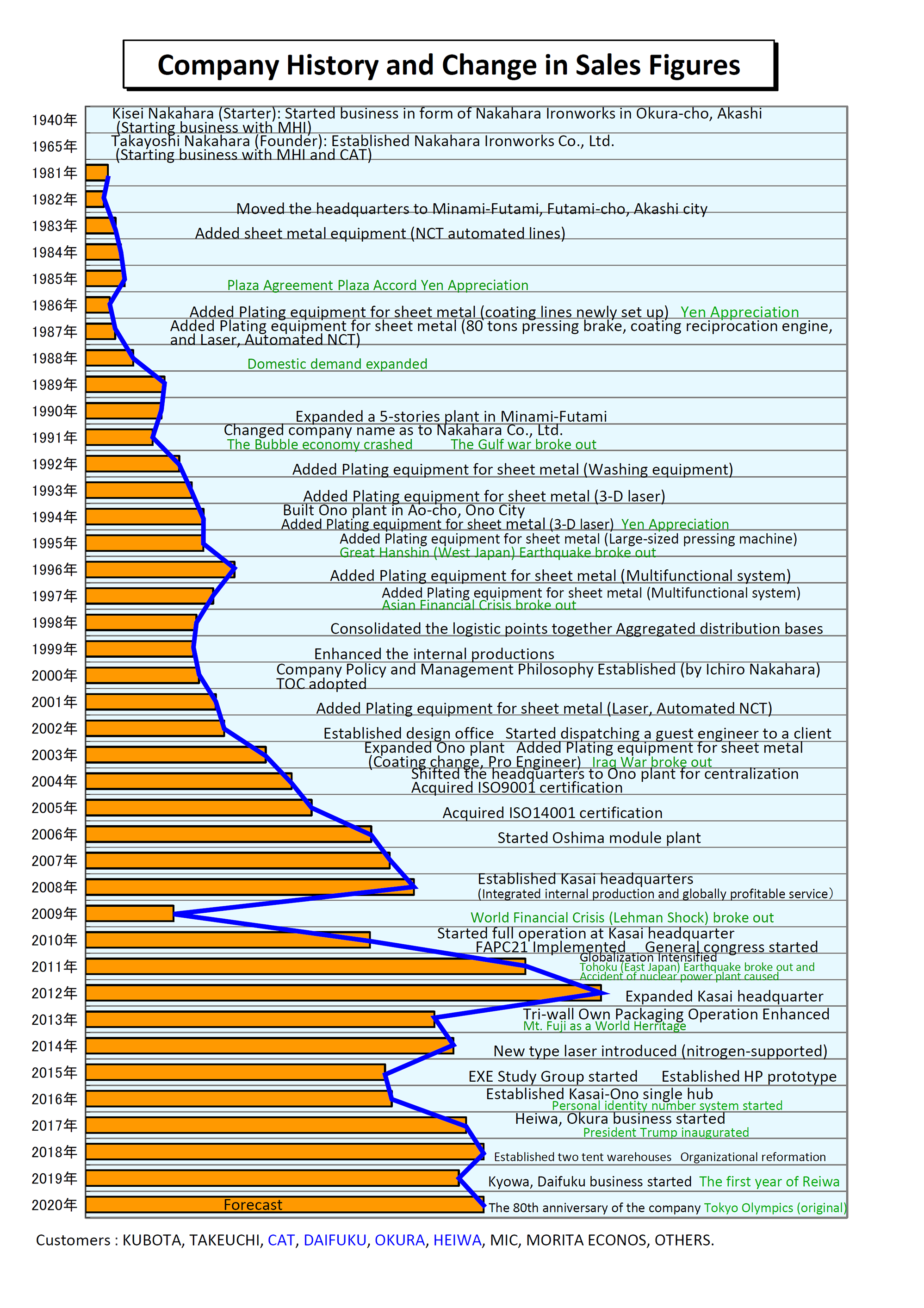

| FOUNDED | 1940 | ||||||||

| CAPITAL | ¥ 95 Million | ||||||||

| LOCATION | 2001-56 Maruyama, Abiki,Kasai,Hyogo,Japan |

||||||||

| No. of EMPLOYEES | 230(INDIRECT35) | ||||||||

| SITE / BUILDING |

KASAI HEAD PLANT

|

||||||||

| MAIN PRODUCTS |

General sheet metal process

|

||||||||

| MAIN EQUIPMENTS |

NC Turret Punching Machine 2units

2Dimensional Laser Cutting Machine 3units 3Dimensional Laser Cutting Machine 4units Hydrallic Press 22000KN With Handing Robot 2set Blake Press 9units Welding Robot 10units CO2 Welding Power Source 60units Spot Welding Power Source 7units Paint Line (Kation 1units,Powder 2units,Solvent 1units) 3D Measuring Machine 1set Digital ultrasonic flaw detector 3D Cad Pro-E 5units AP100 7units IRON WORKER 1units Tapping Machine 1units Deburring Machine 1units Set Press 1units |

||||||||

| MAIN CUSTOMERS | KUBOTA, TAKEUCHI, CAT , DAIFUKU, OKURA, HEIWA , MIC, MORITA ECONOS, OTHERS. |

BANK | MINATO, MIZUHO, TAJIMA, NISSIN, JFC. |

||||||

We, NAKAHARA, can supply the following process.

Our company, included designing, is enable to support general sheet metal

process from material and processing to JIT delivery through integrated

manufacuring internal production.

process from material and processing to JIT delivery through integrated

manufacuring internal production.

General sheet metal process

Mainly steel (0.6 mm to 9 mm)Specialty with thin sheet metal

Punching

Cutting

Bending

Press

Drawing

Welding

Finishing

Painting(E-coat, Powder coat, Solvent coat)

Outfitting

Delivery

Product Management(Install FAPC21)

Equipments

NC Turret Punchung Machine

2Dimensional Laser Cutting Machine

3Dimensional Laser Cutting Machine

Blake Press(Available bending to 4000 length)

Hydrallic Press 22000KN With Handing Robot

(Available to 3500 length)

Welding Robot

CO2 Welding Powet Source

Spot Welding Powet Source

Paint Line(Kation, Powder, Solvent)

(2000 length × 1200 width × 1500 height)

Suface Table(2500×1500、4000×2500)

3D Measuring Machine

Digital ultrasonic flaw detector

3D Cad Pro-E

Acquisition ISO9001 & ISO14001

Acquisition of CAT approval qualification

Mainly steel (0.6 mm to 9 mm)Specialty with thin sheet metal

Punching

Cutting

Bending

Press

Drawing

Welding

Finishing

Painting(E-coat, Powder coat, Solvent coat)

Outfitting

Delivery

Product Management(Install FAPC21)

Equipments

NC Turret Punchung Machine

2Dimensional Laser Cutting Machine

3Dimensional Laser Cutting Machine

Blake Press(Available bending to 4000 length)

Hydrallic Press 22000KN With Handing Robot

(Available to 3500 length)

Welding Robot

CO2 Welding Powet Source

Spot Welding Powet Source

Paint Line(Kation, Powder, Solvent)

(2000 length × 1200 width × 1500 height)

Suface Table(2500×1500、4000×2500)

3D Measuring Machine

Digital ultrasonic flaw detector

3D Cad Pro-E

Acquisition ISO9001 & ISO14001

Acquisition of CAT approval qualification

|

|

|

|

|

|

|

|

| KASAI HEAD PLANT | ONO PLANT |

| Single Hub | |

| made in Japan | |

Our design group executes proposal design and development cooperative works.